Functioning

Function: The resin and hardener are stored separately in the two-chamber cartridge and are only mixed into a mortar when the static mixer is pressed out. The static mixer ensures bubble-free mixing of the two components and protects the injection mortar from hardening inside the cartridge. The pressed out injection mortar completely encloses the anchor, bonds with the borehole wall and seals the borehole. For multiple use of an injection mortar, the static mixer is not removed after the first use. The mortar hardens inside the static mixer, which is not replaced until the next use

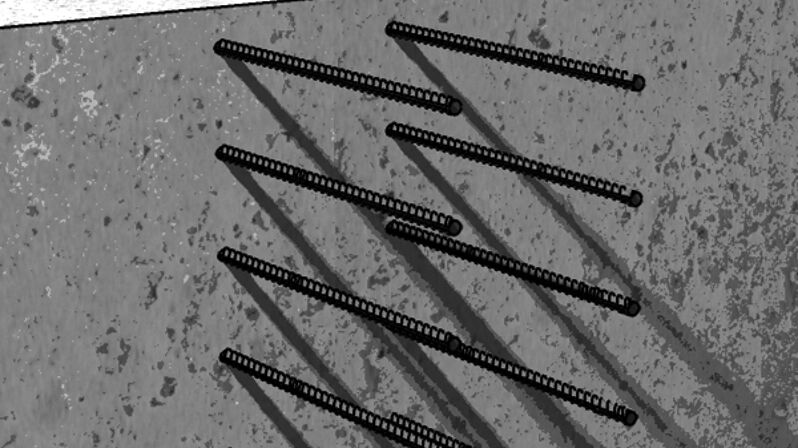

Installation: The Upat injection mortar UPM 55 is installed with the Upat anchor rods in the push-in or push-through installation and with the Upat internally threaded anchors in the push-in installation.

Drill the hole, clean and fill the hole. Glue in the anchor. Screw on the attachment - finished. The anchor is pressed into the filled drill hole by hand with slight twisting movements. The temperature in the building material must not fall below the specified minimum value while the mortar is curing. Minimum cartridge temperature +5°C

Tools: Drill, drilling machine, blow-out tool (UPM AB), cleaning brush (UP BS), dispenser gun (UPM DM P/AM), torque spanner